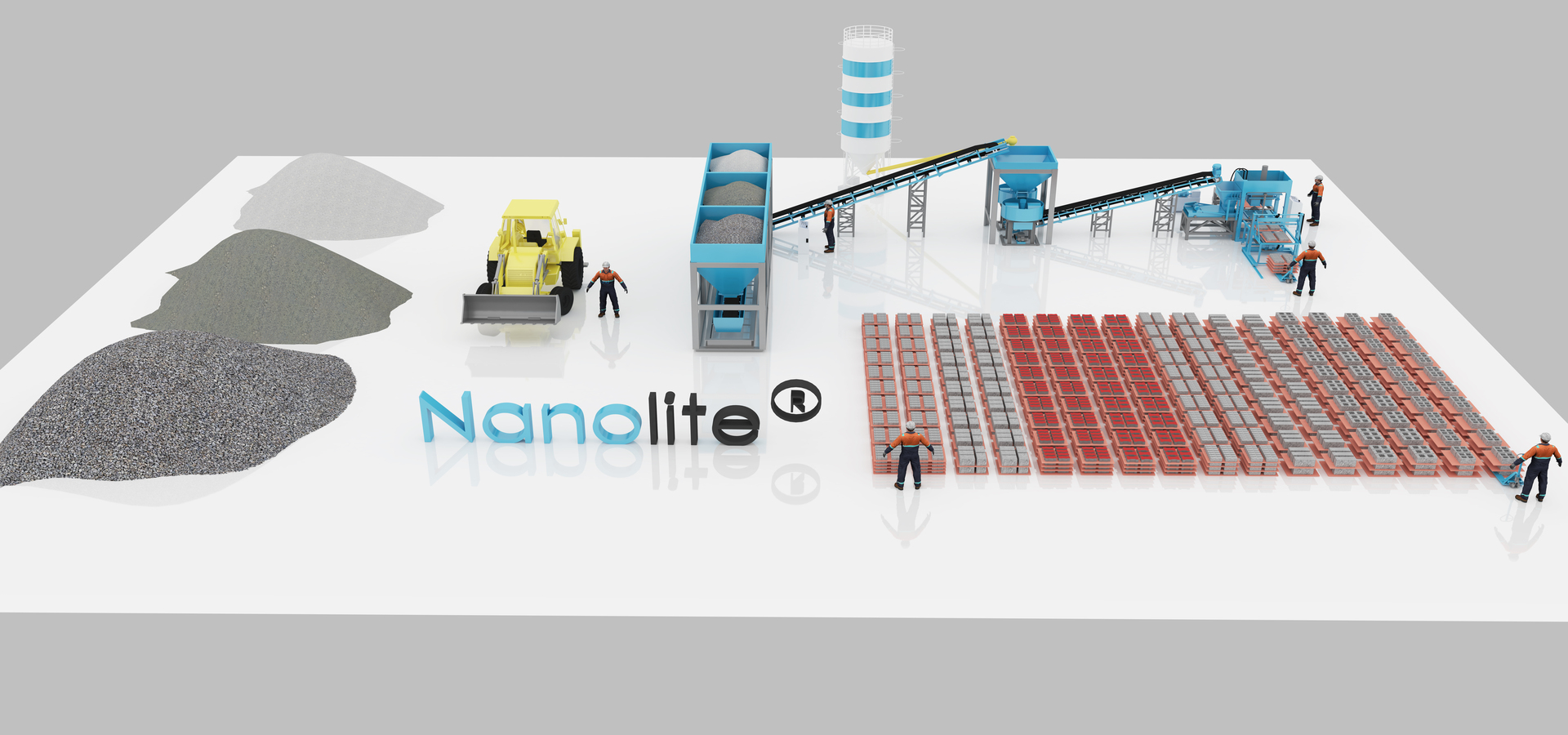

Flyash Bricks & Paver Blocks Plant

Technology

The Nanolite Automatic Flyash Brick & Paver Block Machine is capable of producing various products such as Flyash Bricks, Solid Concrete Blocks, Interlocking Pavers, Hollow Blocks, Kerbstones, Ventilation blocks etc.

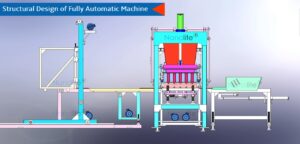

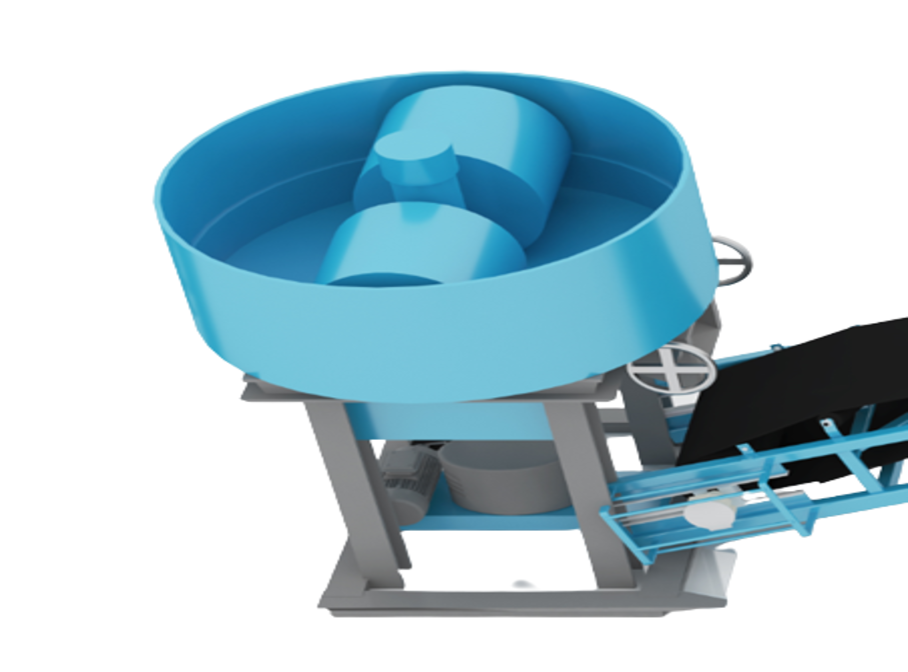

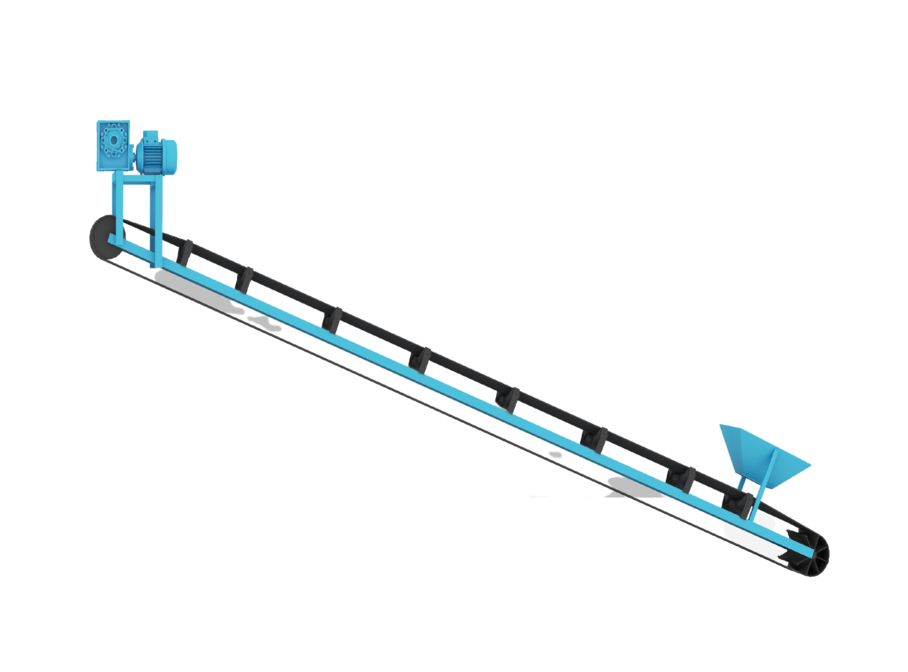

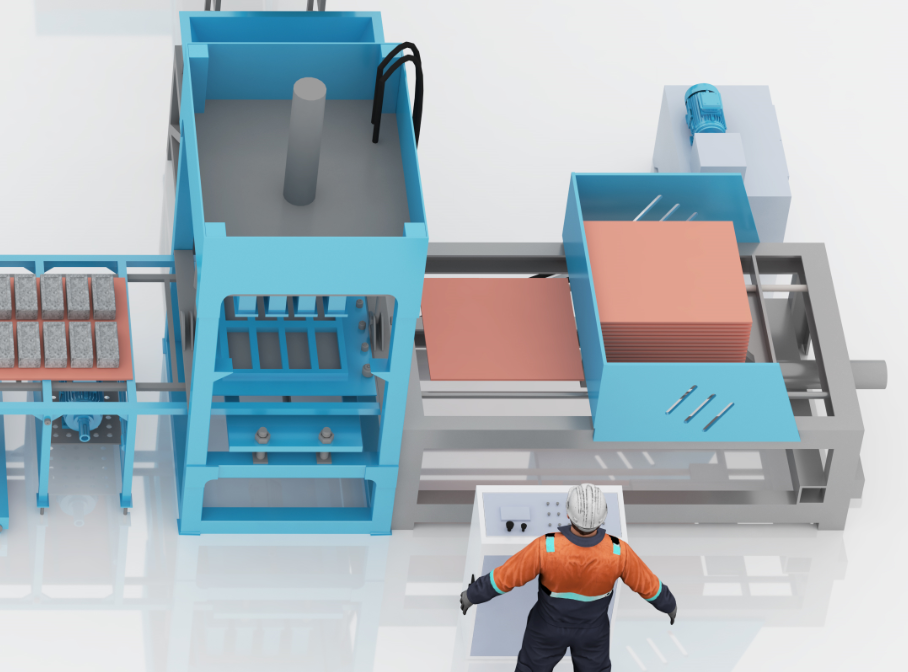

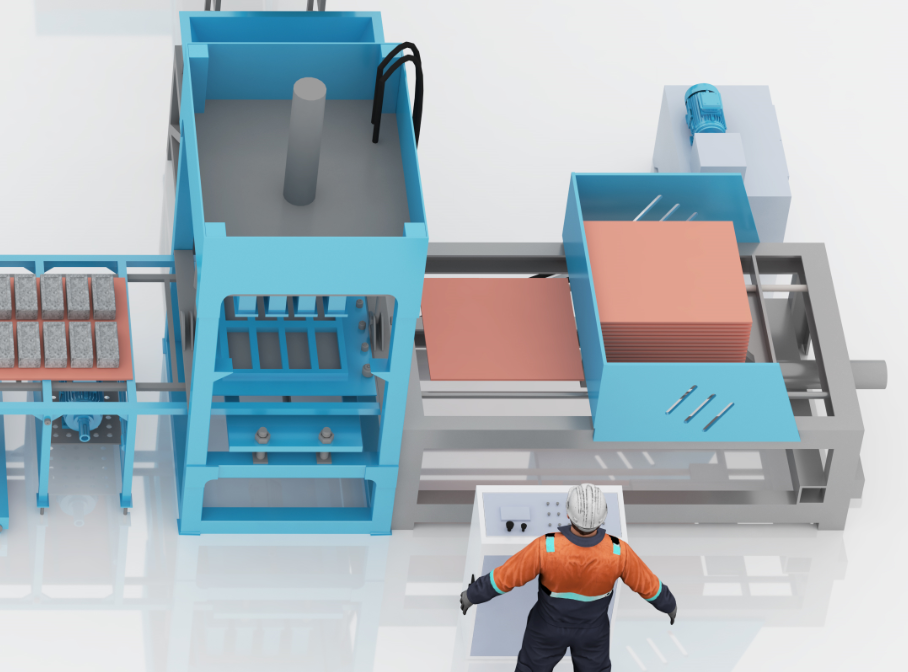

The raw materials are loaded into the mixer(s) trough a fully automated batching plant or manually based on the planned production capacity. The ratios of raw material to be feeded are based on the target product strength, application, local availability of raw material and other specifications. The specially designed pan mixer would thoroughly mix the material till the required uniform texture is achieved. Thus obtained wet concrete is moved to the Hydro-Vibro pressing machine trough conveyer belt. The material would be stored in the hopper and the concrete feeder would load the material to the mould box which is loaded with a wooden or recycled plastic pallet. High frequency vibrators would ensure uniform loading of material in the mould. Once the material is loaded the hydraulic press along with high frequency vibration compacts the material without leaving any air gap in the concrete. This ensure the material attain high strength and accurate edges. Auto stacker system would stack these pallets with freshly produced bricks ensuring low handling damages. Nanolite’s specially design Fully automated Hydro-Vibro pressing machine runs on the PLC system without any manual intervention.

Good Curing gives good strength and dimensional stability to Bricks. Bricks are cured by Water Curing procedure for 14 – 28 days. Because of great-Engineered properties, NANOLITE Bricks have become popular in wide range of applications in construction sector.

Applications

The products produced in this plant can be used in various applications like

Flyash Bricks

High Raise Buildings

Commercial and Residential

buildings

Industrial Buildings and

Sheds

Concrete Blocks

Commercial and Residential

buildings

Compound walls

Infrastructure projects

Retaining Walls

Paver Blocks

Roads

Fuel Stations

Parking Lots

Industrial Zones for movement

of heavy load vehicles

Advantages

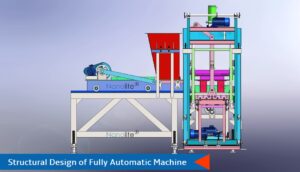

✔ Machine designed to precision using licensed Solid Works Software

✔ Can produce multiple products on single machine

✔ Advanced Hydro-Vibro pressing technology

✔ Achieves high strength upto M45 grade

✔ High quality bricks/blocks with perfect edges can be achieved

Easily inter changeable mould system

✔ Automated Batching plant can be used for faster material loading

✔ PLC controlled Fully automatic machine

✔ Best in class Seimens or Delta PLC will be used

✔ All motors will be Crompton, Havells or Bharat Bhijili make

✔ All hydraulic components are best in class from Yuken, Dowty, Hydroline and Parker make

✔ Less Cycle time (16-18 seconds)

✔ Heavy Duty Robust design

✔ Automatic pallet and concrete feeding system

✔ Auto stacker to avoid handling damage

✔ Heavy duty pan mixer designed to ensure quick and uniform mixing of raw materials

✔ Wide range of machineries from Production capacity of machines is 500 to 3500 bricks per hour

Raw Materials

Cement

Cement

Flyash

Flyash

Stone Chips

Stone Chips

Sand

Sand

Water

Water

Products

Flyash Brick (With Frog)

Flyash Brick (Without Frog)

Solid Concrete

Block

I-Shape Interlocking Paver

Zig-Zag Shape Interlocking Paver

Kerb

Stone

Ventilation

Block

Plant Types

| 4 Cavity Technical Specifications | |

|---|---|

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 4 |

| No of Bricks | 480 per Hour |

| No of Bricks Per Stroke | 3840 |

| Shed Area Required | 2800 Sq. ft. |

| Plant Area Required | 1800 Sq. Yards |

| Man Power Required | 5 |

| Pallet Size | 550 x 340 x 15 mm |

| Cycle Time | 30 Seconds |

| Hydraulic Tank Capacity | 100 Liters |

| Total Power | 25HP |

| 6 Cavity Technical Specifications | |

|---|---|

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 6 |

| No of Bricks | 720 per Hour |

| No of Bricks Per Stroke | 5760 |

| Shed Area Required | 3000 Sq. ft. |

| Plant Area Required | 2000 Sq. Yards |

| Man Power Required | 5 |

| Pallet Size | 550 x 420 x 18 mm |

| Cycle Time | 30 Seconds |

| Hydraulic Tank Capacity | 100 Liters |

| Total Power | 28HP |

| 6 Cavity Technical Specifications | |

|---|---|

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 6 |

| No of Bricks | 1200 per Hour |

| No of Bricks (8hrs) | 9600 Per Shift |

| Shed Area Required | 3800 Sq. ft. |

| Plant Area Required | 2200 Sq. Yards |

| Man Power Required | 5 |

| Pallet Size | 550 x 420 x 18 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Tank Capacity | 15 Ton / 270 Liters |

| Total Power | 42HP |

| PLC Make | Siemens /Delta/Mitsubishi |

| 10 Cavity Technical Specifications | |

|---|---|

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 10 |

| No of Bricks | 2000 per Hour |

| No of Bricks (8hrs) | 16000 Per Shift |

| Shed Area Required | 4000 Sq. ft. |

| Plant Area Required | 2500 Sq. Yards |

| Man Power Required | 6 |

| Pallet Size | 550 x 675 x 18 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Tank Capacity | 15 Ton / 270 Liters |

| Total Power | 45HP |

| PLC Make | Siemens/Delta/Mitsubishi |

| 14 Cavity Technical Specifications | |

|---|---|

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 14 |

| No of Bricks | 2800 per Hour |

| No of Bricks (8hrs) | 22000 Per Shift |

| Shed Area Required | 4500 Sq. ft. |

| Plant Area Required | 3000 Sq. Yards |

| Man Power Required | 8 |

| Pallet Size | 550 x 975 x 25 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Tank Capacity | 25 Ton / 350 Liters |

| Total Power | 60HP |

| PLC Make | Siemens/Delta/Mitsubishi |

| 16 Cavity Technical Specifications | |

|---|---|

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 16 |

| No of Bricks | 3400 per Hour |

| No of Bricks (8hrs) | 27000 Per Shift |

| Shed Area Required | 5000 Sq. ft. |

| Plant Area Required | 1 Acre |

| Man Power Required | 8 |

| Pallet Size | 820 x 850 x 25 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Tank Capacity | 25 Ton / 270 Liters |

| Total Power | 65HP |

| PLC Make | Siemens/Delta/Mitsubishi |

| Batching Plant Technical Specifications | |

|---|---|

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 16 |

| No of Bricks | 3400 per Hour |

| No of Bricks (8hrs) | 27000 Per Shift |

| Shed Area Required | 5000 Sq. ft. |

| Plant Area Required | 1 Acre |

| Man Power Required | 8 |

| Pallet Size | 820 x 850 x 25 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Tank Capacity | 25 Ton / 270 Liters |

| Total Power | 65HP |

| PLC Make | Siemens/Delta/Mitsubishi |

Specification Of Equipment

Production Machinery

Pan Mixer

Capactity: 250 kgs / 500kgs / 750 kgs

Power: 7.5HP / 10 HP / 12.5 HP

Gear Box: Helical Bottom Mounted

Mixing Arms: Rollers and Blades

Liners: Bottom and Side

Material: MS

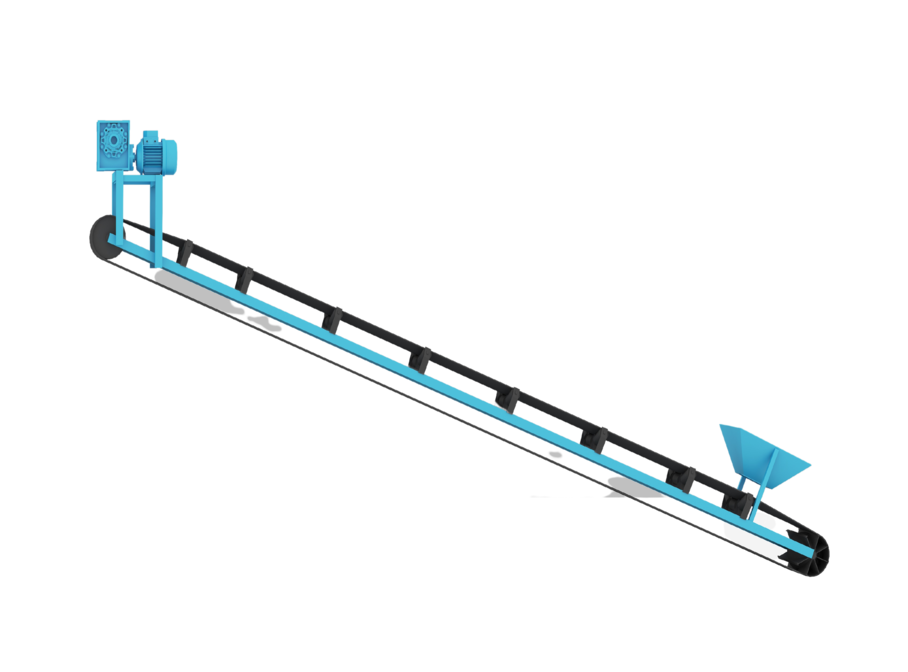

Conveyer Belt

Length: 18 ft

Motor: Flange Mounted

Gearbox: Helical Type

Structure: MS

Power: 2HP

Electric Control Panel

Types: Control Desk

PLC: Seimens Make

HMI: Proface Make

Switch Gear: L&T or Seimens

VFD: Delta

Structure: MS with Powder coating

Hydro-Vibro Pressing Machine

Types: Semi-Automatic

Capactity: 4 / 6 Cavity

Power: 10 / 22.5 HP

Components: Concrete Feeder,

Pallet Pusher, Die & Mould set

Operation: Lever Based

Vibrators: 5HP

Power Pack Capacity: 100 litres

Hydraulic Pressure: 5 Tons

Hydro-Vibro Pressing Machine

Types: Fully Automatic

Capactity: 6 / 10 / 14 / 18 Cavity

Power: 22.5 / 27 / 32 / 37 HP

Components: Concrete Feeder,

Pallet Feeder, Die & Mould set

Operation: Automated with PLC

Vibrators: 7.5 HP / 10 HP / 15 HP

Power Pack Capacity: 270 / 350 litres

Hydraulic Pressure: 15 / 25 Tons

Auto Stacker

Type: Fully Automatic

Power: 4 HP

Structure: MS

Components: Pallet Mover, Pallet

Lifter, Lift Mover

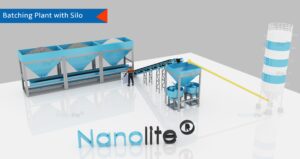

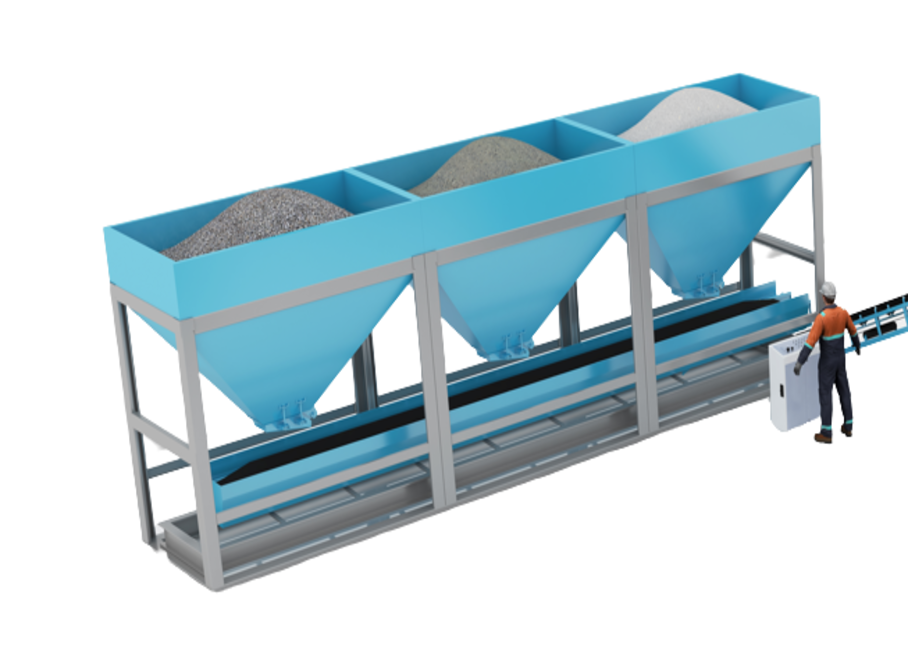

Feeding Machinery – Batching Plant

Storage Bins

Capacity: 3 Bins of 2 cu.m

capacity each

Doors: Pneumatic operated

Weighing mechanism: Load weighing Conveyer Belt with load cells

Structure: MS

Compressor: 3HP ELGI Make

Power: 2HP For Conveyer Belt

Conveyer Belt

Length: 18 ft

Motor: Flange Mounted

Gearbox: Helical Type

Structure: MS

Power: 2HP

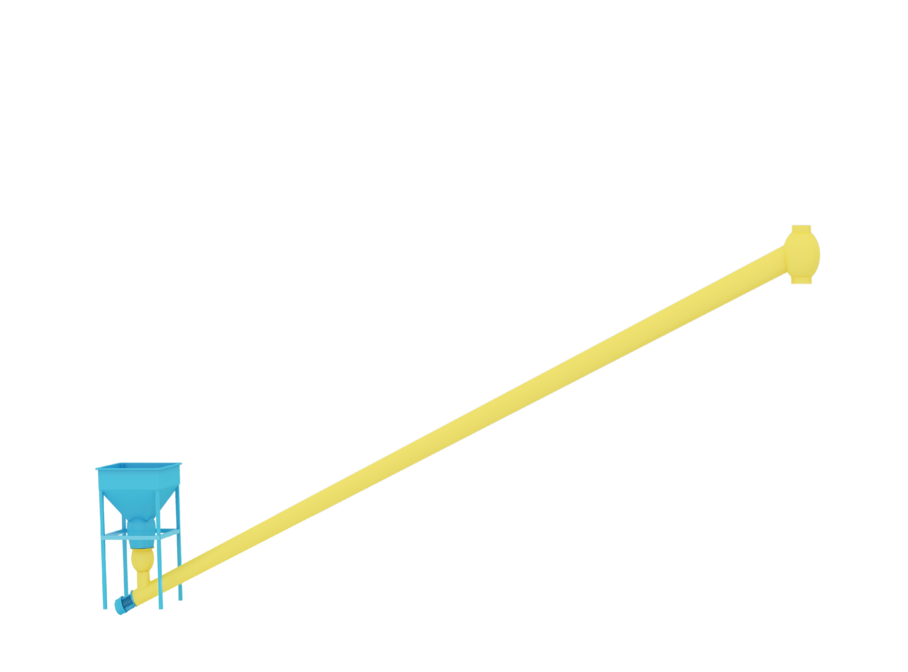

Screw Conveyer

Length: 20 Ft

Motor: Flange Mounted

Gearbox: Helical Type

Structure: MS

Dia: 168mm with Universal

outlet and inlet

Power: 5HP

Silo

Capacity: 60 Tons / 100 Tons

Material: Cement / Flyash

Discharge: Screw Conveyer

Blower: 40 HP / 50 HP

Blower Make: Roots

Conveyer Make: Cosben

Dust Collector: Bottom / Top

FAQs

The automatic flyash brick machinery will take around 45days for delivery from the date of receiving order with advance. Post delivery it will 1 week for installation on the machinery and trail production.

Yes, our team of technicians will visit your site and does installation of the machine and will provide training on operation and maintenance of machinery. Our team will also do trail production and ensure high quality output is delivered.

The most important difference between blocks and bricks is in the size. Bricks are generally in the size of 9 * 4 * 3 inches or 230 * 110 * 75mm and blocks are generally in bigger size.

Yes we can produce concrete bricks without flyash in the same machine

It depends on the plant size and type. A basic 4 cavity would require 5 people for production and the fully automatic 18 cavity machine will require upto 10 man power

Machine Type | Semi-Automatic | Semi-Automatic | Fully-Automatic | Fully-Automatic | Fully-Automatic | Fully-Automatic |

Machine Size | 4 Cavity

| 6 Cavity | 6 Cavity | 6 Cavity | 6 Cavity | 6 Cavity |

Man Power Required | 5 | 5 | 5 | 6 | 8 | 10 |

Nanolite has a dedicated team of service technicians who would address any complaint instantly and provide support over call or video calls. When required the team will travel

Nanolite has a dedicated team of service technicians who would address any complaint instantly and provide support over call or video calls. When required the team will travel

Nanolite has a dedicated team of service technicians who would address any complaint instantly and provide support over call or video calls. When required the team will travel

Nanolite has a dedicated team of service technicians who would address any complaint instantly and provide support over call or video calls. When required the team will travel

Nanolite has a dedicated team of service technicians who would address any complaint instantly and provide support over call or video calls. When required the team will travel

Get in Touch

Nanolite Infratech Pvt.Ltd. Level II, M K Reddy’s Mansion Above Adidas Showroom Dr. A S Rao Nagar, ECIL Post Hyderabad – 500062

Call us on

+91 94915 39933

+91 94916 39933

+91 94917 39933

+91 94918 39933

Email us

sales@nanolite.in