Get in Touch

Nanolite Infratech Pvt.Ltd. Level II, M K Reddy’s Mansion Above Adidas Showroom Dr. A S Rao Nagar, ECIL Post Hyderabad – 500062

Call us on

+91 94915 39933

+91 94916 39933

+91 94917 39933

+91 94918 39933

Email us

sales@nanolite.in

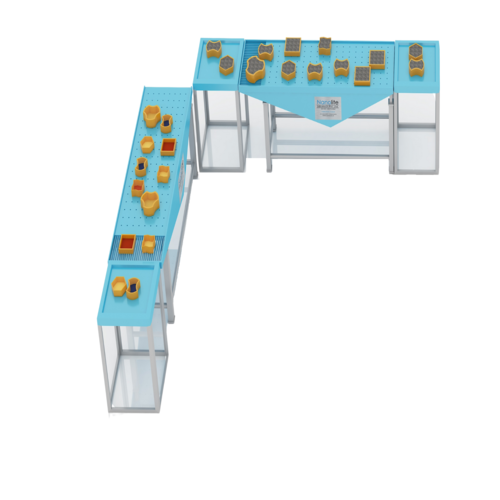

The Nanolite Pavers Block & Designer Tile Machine is capable of producing 350+ designs of products such as Interlocking Paver Blocks, Designer Parking Tiles, Kerb Stones, Cover Blocks, Bricks etc. The major raw material used in the machine includes Cement, Flyash, Stone Chips, Stone dust or sand, and water. Additional chemicals such as color oxide, hardner and lacquer for various applications. We use vibrating table technology to produce these products. Vibrating tables eliminate the air gaps in the concrete and make it uniform and helps in achieving high strength

The process of producing these products include feeding the raw materials into the mixer. The ratios of raw material to be feeded are based on the target product strength, application, local availability of raw material and other specifications. The specially designed pan mixer would thoroughly mix the material till the required uniform texture and consistency is achieved. Thus, obtained wet concrete is moved to the Vibrating Table setup machine trough concrete trolleys. In parallel a color mixer would mix the raw material for the top layer which will be used to achieve the required color and fine finish. The first layer of the material from the color mixer will be loaded into the mould and placed on the vibrating table. The mould with the help of the vibrators would move forward and reach the other end of the table. Now the concrete mix would be loaded into the moulds and placed on the second vibrating table. With the help of vibration, the mould would move further and reach the other end where it will be stacked to attain initial strength. The next day the material will be demoulded get open for complete drying. Once totally dry a lacquer or coating oil can be applied to achieve glossy finish.

Good Curing gives good strength and dimensional stability to Pavers, Tiles, bricks etc. These products need to be cured by Water Curing procedure for 14 – 28 days. By using the chemical hardner the curing timing can be reduced drastically. Because of great-Engineered properties, NANOLITE Bricks have become popular in wide range of applications in construction sector.

The products produced in this plant can be used in various applications like

Parking Lots

Walkways or Footpaths

Road

Fuel Stations

Industrial flooring

Road dividers

Walkways or Footpaths

Slabs

Columns

Precast Concrete products

Residential Building Construction

Commercial Building Construction

✔ 300+ products on single machine

✔ High production capacity of 2500 – 4000 products per shift

✔ Wide range of applications catering to high market demand

✔ Heavy Duty Robust design

✔ Less man power required due to simple process

✔ Multiple types of products can be produced at the same time

✔ Heavy vibration at 2880 RPM ensures void free premium finish

✔ Availability of different types of Moulds like Silicon Plastic, PVC or Rubber

✔ High quality bricks with perfect edges achieved

✔ Heavy duty pan and drum mixers designed to ensure quick and uniform mixing of raw materials

Note: The above mentioned products can be produced in different dimensions based on requirement.

| Technical Specifications | |

| Mixer Type | Drum Mixer |

| Mixer Capacity | 10/7 cu.ft |

| Production Capacity | 300 Per hour |

| Production Capacity | 2500 pre shift |

| Shed Area required | 500 Sq.ft |

| Plant Area Required | 1200 Sq. Yards |

| Man Power Required | 6 |

| Total Power | 15HP |

| Technical Specifications | |

| Mixer Type | Pan Mixer |

| Mixer Capacity | 250 kg |

| Production Capacity | 375 Per hour |

| Production Capacity | 3000 per shift |

| Shed Area required | 500 Sq.ft |

| Plant Area Required | 1200 Sq. Yards |

| Man Power Required | 6 |

| Total Power | 15HP |

| Technical Specifications | |

| Mixer Type | Pan Mixer |

| Mixer Capacity | 500 kg |

| Production Capacity | 500 Per hour |

| Production Capacity | 4000 per shift |

| Shed Area required | 600 Sq. ft. |

| Plant Area Required | 1500 Sq. Yards |

| Man Power Required | 7 |

| Total Power | 18HP |

Note : The production capacities mentioned above are based on tiles or pavers

Capactity: 400 kgs

Power: 7.5HP

Gear Box: Top Bottom Mounted

Mixing Arms: Rollers and Blades

Liners: Bottom and Side

Material: MS

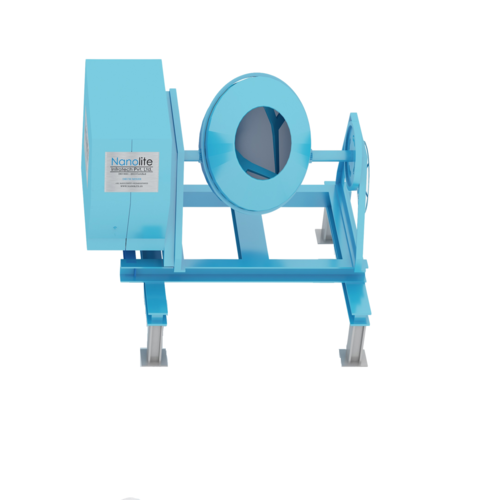

Concrete Drum Mixer

Capactity: 10/7 cu.ft or 1 Bag Mixer

Operation Type: Electric Motor / Diesel Engine

Power: 5HP

Tyres: Optional

Material: MS

Capacity: 200 Kgs

Power: 3HP

Blades: Removable

Material: MS

Dimension: 10 ft x 2.5 ft

Power: 3HP

Motor RPM: 2880

Mounting: U Shear Mounts

Top Plate: 8mm

Material: MS

Body: 4mm

Capacity: 500 kgs

Tyres: Solid

The Paver Block and Tile machinery will take around 14days for delivery from the date of receiving order with advance. Post-delivery it will 2 days for installation on the machinery and trail production.

Yes, our team of technicians will visit your site and does installation of the machine and will provide training on operation and maintenance of machinery. Our team will also do trail production and ensure high quality output is delivered.

The parking tiles are generally used for parking lots or footpaths. They are generally produced to withstand a load upto 9-ton vehicle

Paver blocks can be produced in different thickness to withstand different kind of loads. 60mm thickness pavers can have a strength upto M30 grade, 80mm thickness pavers can have a strength upto M35 grade, 100mm thickness pavers can have a strength upto M40 grade.

Yes, this machine support production of bricks using the brick moulds

Nanolite Infratech Pvt.Ltd. Level II, M K Reddy’s Mansion Above Adidas Showroom Dr. A S Rao Nagar, ECIL Post Hyderabad – 500062

+91 94915 39933

+91 94916 39933

+91 94917 39933

+91 94918 39933

sales@nanolite.in

| Technical Specifications | |

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 4 |

| No of Bricks per Hour | 480 |

| No of Bricks Per Stroke | 3840 |

| Shed Area required | 2800 Sq. ft. |

| Plant Area Required | 1800 Sq. Yards |

| Man Power Required | 5 |

| Pallet Size | 550 x 340 x 15 mm |

| Cycle Time | 30 Seconds |

| Hydraulic Tank Capacity | 100 Liters |

| Total Power | 25HP |

| Technical Specifications | |

| Plant Type | Semi Automatic |

| No of Bricks Per Stroke | 6 |

| No of Bricks per Hour | 720 |

| No of Bricks Per Stroke | 5760 |

| Shed Area required | 3000 Sq. ft. |

| Plant Area Required | 2000 Sq. Yards |

| Man Power Required | 5 |

| Pallet Size | 550 x 420 x 18 mm |

| Cycle Time | 30 Seconds |

| Hydraulic Tank Capacity | 100 Liters |

| Total Power | 28HP |

| Technical Specifications | |

| Plant Type | Fully Automatic |

| No of Bricks Per Stroke | 6 |

| No of Bricks per Hour | 1200 |

| No of Bricks Per Shift (8hrs) | 9600 |

| Shed Area required | 3800 Sq. ft. |

| Plant Area Required | 2200 Sq. Yards |

| Man Power Required | 5 |

| Pallet Size | 550 x 420 x 18 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Pressure / Tank Capacity | 15 Ton / 270 Liters |

| Total Power | 42HP |

| PLC Make | Siemens /Delta/Mitsubishi |

| Technical Specifications | |

| Plant Type | Fully Automatic |

| No of Bricks Per Stroke | 10 |

| No of Bricks per Hour | 2000 |

| No of Bricks Per Shift (8hrs) | 16000 |

| Shed Area required | 4000 Sq. ft. |

| Plant Area Required | 2500 Sq. Yards |

| Man Power Required | 6 |

| Pallet Size | 550 x 675 x 18 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Pressure / Tank Capacity | 15 Ton / 270 Liters |

| Total Power | 45HP |

| PLC Make | Siemens /Delta/Mitsubishi |

| Technical Specifications | |

| Plant Type | Fully Automatic |

| No of Bricks Per Stroke | 14 |

| No of Bricks per Hour | 2800 |

| No of Bricks Per Shift (8hrs) | 22000 |

| Shed Area required | 4500 Sq. ft. |

| Plant Area Required | 3000 Sq. Yards |

| Man Power Required | 8 |

| Pallet Size | 550 x 975 x 25 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Pressure / Tank Capacity | 25 Ton / 350 Liters |

| Total Power | 60HP |

| PLC Make | Siemens /Delta/Mitsubishi |

| Technical Specifications | |

| Plant Type | Fully Automatic |

| No of Bricks Per Stroke | 18 |

| No of Bricks per Hour | 3400 |

| No of Bricks Per Shift (8hrs) | 27000 |

| Shed Area required | 5000 Sq. ft. |

| Plant Area Required | 1 Acre |

| Man Power Required | 8 |

| Pallet Size | 820 x 850 x 25 mm |

| Cycle Time | 16-20 Seconds |

| Hydraulic Pressure / Tank Capacity | 25 Ton / 350 Liters |

| Total Power | 65HP |

| PLC Make | Siemens /Delta/Mitsubishi |

| Technical Specifications | |

| No of Bins | 3 |

| Capacity of Each Bin | 5 cu.m |

| Bin Opening | Pneumatic |

| Weighing System | Load Cells |

| Output per hour | 20 cu.m |

| Conveyer for aggregates | Belt Conveyer |

| Conveyer for cement | Screw Conveyer |

| Total Power | 18HP |

| Automation | Delta/Schneider |